Description

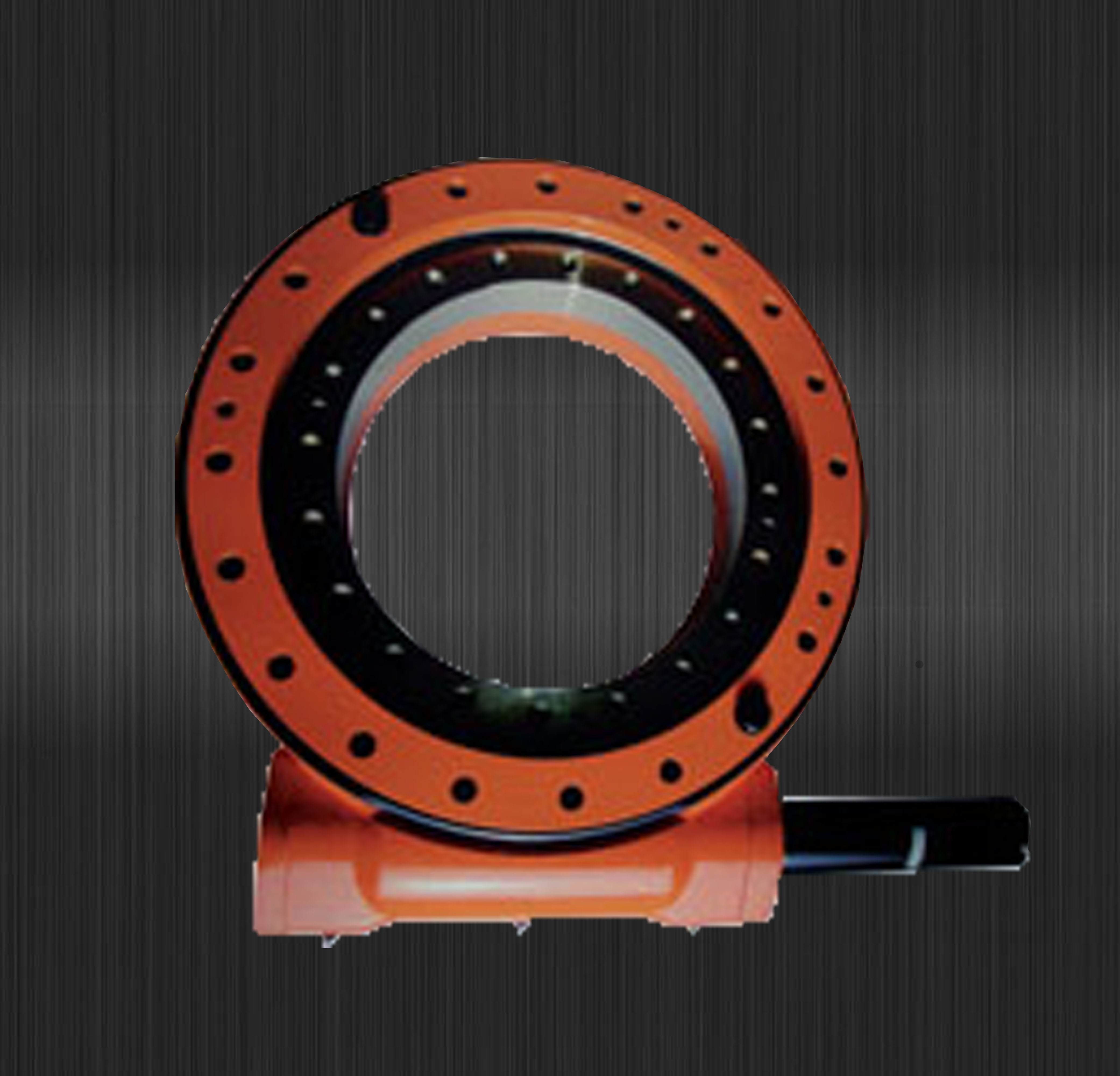

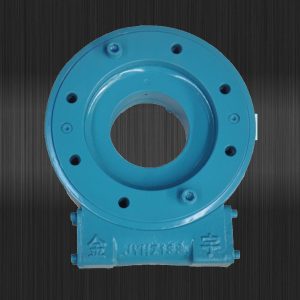

On the rotary reducer installation and debugging

Nut size shall comply with the relevant provisions of the national standard GB/ t1230-2006 of the People’s Republic of China and the national standard GB/ t1230-2006 of the People’s Republic of China. Flat washers after heat treatment shall be adopted and the appropriate strength grade shall be selected according to the force of rotary support. Spring washers are prohibited.

According to the design regulations of the main engine, a certain pre-tightening force shall be guaranteed. Unless otherwise specified, the general pre-tightening force shall be 0.7 times the yield limit of the bolt. A small amount of oil is allowed on the thread during tightening. Bolt clamping length LK 5d(d is bolt diameter)

To avoid deviation between bolt locking forces, please pay attention to the following clauses.

1. Oil a small amount of thread and screw head to ensure uniform friction resistance (adhesive is not allowed)

2. Load bolts including washers more frequently, if necessary, by 30%, 80% and 100%.

For hydraulic motors, the pre-loaded locking force cannot exceed 90% of the finished product.

After the installation work is finished, the dirt and dust on the rotary drive shall be removed in time, and the leaking part shall be coated with anti-rust paint, and the power source shall be adjusted.

Reviews

There are no reviews yet.